We recently completed a project for an end user needing a custom solution. Below is the problem and solution, as well as the importance of ergonomics throughout the process.

The Problem:

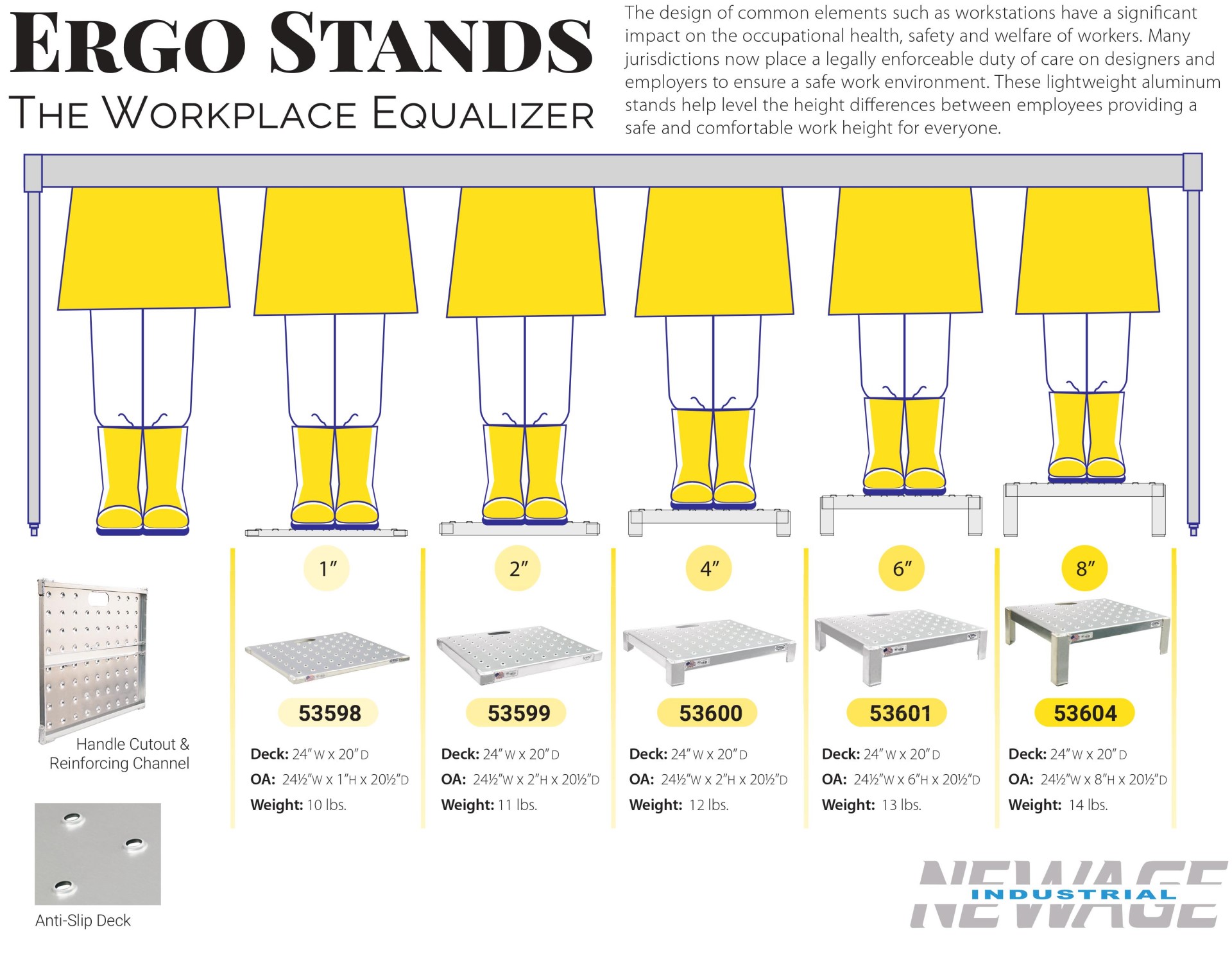

A customer was seeking a solution to level height differences among employees at non-adjustable, shared workstations to provide a safer and more comfortable working height for everyone. They used long tables where multiple associates (of various heights) worked simultaneously while standing. Having one table height for everyone is difficult, since not everyone is the same height. Some people strained to reach higher up, while others were bending for long periods of time. In addition, the floors sometimes became slick and/or greasy, so having good traction was of utmost importance. They needed a safe, ergonomic solution that was lightweight for employees to carry around.

The Solution:

We designed lightweight, yet heavy duty aluminum stands with a carrying handle. They have an anti-slip deck with a perforated top and are manufactured in five (5) different heights, 1” x 2” x 4” x 6” x and 8”. The largest (8″) portable deck weighs only 14lbs. Even a 1” high platform can help a person from slipping in a greasy or slick environment. In wet environments, workers want to feel safe from slipping on the byproducts of assembly line manufacturing. In dry environments, workers need to be elevated to a safe ergonomic height when doing repetitive motions. The stands we developed are a simple solution that adjusts the height of associates without the added risks of instability or the bacteria harboring nature of a traditional step stool. Due to being made from aluminum, they will not rust or corrode and are easy to clean or sanitize. When workers begin their shift, they choose the proper deck height that feels the most comfortable for them to stand on, and position themselves in a safe, ergonomic manner while they work. At the end of their shift, they are cleaned, sanitized, and stored.

The Importance of Ergonomics:

Ergonomics is one of the most important issues we consider in everything thing we build today! We think about even the smallest details such as product height, weight of the product being moved around, handle position, ergonomic issues loading and unloading product, and more! Our goal as a manufacturer is to build products that make the work environment safe and worker friendly.

New Age Industrial is the leading aluminum extruder and fabricator of storage and transportation equipment in the United States. We design and manufacture heavy duty, yet lightweight aluminum products to meet your exact needs. We work with various industries including foodservice, supermarket, and material handling. For more information, contact us today, and our team will help find you the perfect product that fits your needs.

Access the full printable PDF version of this case study by clicking the button below: