We had the opportunity to do a quick Question and Answer (Q&A) Session with Ron Keiswetter, Welding Foreman, to get his thoughts on welding aluminum.

What makes a good welder?

A good welder must have good vision along with good hand-eye coordination. It’s a person who cares about the quality of work they do. It’s a person that can read a tape measure and read a blueprint. It’s a person who is always trying to get better every day. It’s a person who can weld many different products.

What makes New Age’s welds superior to the competition?

We have welders who care about the quality of their welds and the knowledge of what New Age expects of them. They take pride in their work and their welds.

What’s the difference between a good weld and a bad weld?

A good weld penetrates into both pieces of metal. A bad weld either does not penetrate the metal or penetrates too much into the metal, cracks and weakens it.

Our weld.

Competitor’s weld.

Is aluminum different than other metals? How?

Aluminum is much lighter than steel. It is a cleaner metal than steel. In order to weld the metal together, aluminum has to be free of foreign substances, whereas steel does not.

How many welders does New Age have, and how do you choose what products to have them weld?

New Age has twenty-four mig welders and two tig welders on day shift, along with four robot operators and two parts handlers. Night shift has nine welders and three part-time welders; anywhere from two to four robot operators of the nine welders. New Age tries to have all of its welders be versatile in what they can weld. We match them to their physical ability and their skills.

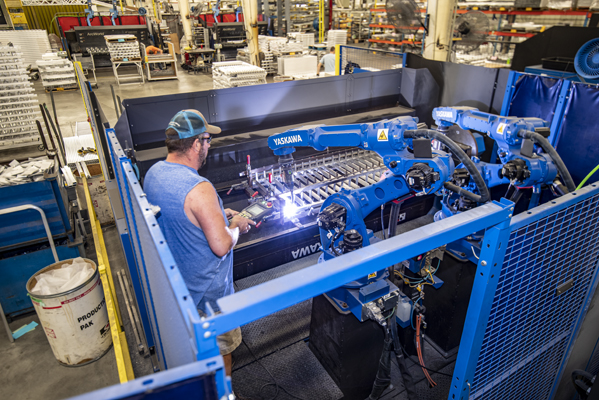

When do you use robotic welders, and how do they work?

New Age uses them on products that we produce large quantities of. They are used to save time on products and lack of manpower that we might have. They do the work of two to three welders. An operator programs the robot where to weld and how to produce the proper weld for each product.

New Age Industrial has over 50 individual welding stations using both MIG and TIG argon gas welding. Our combination of skilled operators and robotics allows us to maintain our industry recognized high standards in welding aluminum. State of the art robotic welders are used to increase our efficiency and lower costs for high volume, repetitive jobs. This frees up our hands-on welding team, for more specialized welds. Visit our website to learn more about our Flexible Manufacturing Process.

New Age Industrial is the leading aluminum extruder and fabricator of storage and transportation equipment in the United States. We use a Flexible Manufacturing Process to design and build heavy-duty yet lightweight aluminum products that can be customized to fit your exact needs, completely stress-free. Our unmatched versatility in product design and in-house team of experts make New Age Industrial the Top Choice for material handling and food service equipment. Our products are Proudly Made in the USA!