In the fast-paced material handling world, efficient and safe transportation of products is paramount. Carts play a vital role in this process, providing a reliable means of moving goods and protecting them from damage. In this blog post, we will explore how carts can be effective solutions for safeguarding both your products and your workforce in the material handling industry.

Customized Cart Designs

One size does not fit all when it comes to carts in the material handling industry. Different products have varying shapes, sizes, and fragility levels, necessitating customized cart designs. Working closely with cart manufacturers or suppliers, you can create tailor-made solutions matching your product requirements. Customization may include adjustable shelving, dividers, securing mechanisms, and specialized padding or cushioning to protect delicate items during transit.

Ergonomic Design for Workforce Safety

Carts that prioritize ergonomic design not only enhance the safety of your workforce but also improve overall productivity. Look for features such as adjustable handle heights, V-shaped handles, cushioned grips, and smooth-rolling casters to minimize worker strain and fatigue. Ergonomically designed carts reduce the risk of injuries, such as back strains or repetitive stress injuries, and promote a healthier work environment.

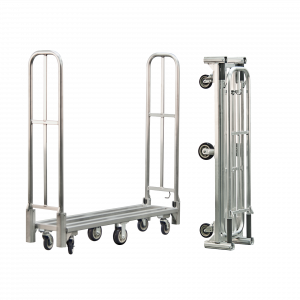

Impact-Resistant Construction

The material handling industry often involves moving goods through busy warehouses, factories, or distribution centers, where collisions and impacts can occur. Investing in carts with impact-resistant construction can provide added protection to both your products and your employees. Opt for carts made from durable materials, such as aluminum, which can withstand impacts and reduce the risk of damage to your valuable goods.

Securement and Containment Features

During transportation, it is crucial to ensure that products remain securely in place within the cart to prevent shifting, falling, or breakage. Carts equipped with securing mechanisms such as straps, latches, or containment walls provide additional protection. Adjustable dividers or compartments can also be incorporated to separate different items, minimizing the potential for collision or damage.

Maneuverability and Flexibility

Efficient material handling relies on the ease of cart maneuverability. Look for carts with swivel casters allowing smooth navigation, even in tight spaces. Consider the type of flooring in your facility and select casters appropriate for the surface, whether it’s hard rubber wheels for smooth floors or pneumatic wheels for uneven terrain. Additionally, carts that offer modular or collapsible features can optimize space utilization and adapt to varying transportation needs.

Safety Accessories

Enhancing safety in the material handling industry goes beyond the carts’ design. Consider incorporating safety accessories such as reflective strips or lights for increased visibility in low-light environments. Anti-slip surfaces on cart platforms can prevent slips and falls, while integrated braking systems provide stability and prevent unintended movement.

Compliance with Industry Regulations

When selecting carts for your material handling operations, ensure they comply with relevant industry regulations and safety standards. Compliance protects your products and employees and helps you avoid potential legal issues. Research applicable guidelines and standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the American National Standards Institute (ANSI), to ensure your carts meet the necessary requirements.

Carts serve as invaluable solutions in the material handling industry, safeguarding your products and workforce. By prioritizing customized designs, ergonomic features, impact-resistant construction, securement mechanisms, maneuverability, safety accessories, and regulatory compliance, you can enhance efficiency, minimize damage, and protect the well-being of your employees. Investing in high-quality carts tailored to your specific needs will undoubtedly yield long-term benefits, ensuring the safe and efficient transportation of goods in your material handling operations.

New Age Industrial is the leading aluminum extruder and fabricator of storage and transportation equipment in the United States. We use a Flexible Manufacturing Process to design and build heavy-duty yet lightweight aluminum products that can be customized to fit your exact needs, completely stress-free. Our unmatched versatility in product design and in-house team of experts make New Age Industrial the Top Choice for material handling and food service equipment. Our products are Proudly Made in the USA!